Applications & Specific Features

-Main tank to daily service tank oil transfer.

-Oil supply to one or multiple generators.

-Installations with large height differences between main storage and daily service tanks.

-Any oil supply for ‘tank to tank’ automated by a signal from the daily tank level switch to the FP unit.

-Special FP units available for aggressive or heated nonstandard fuels.

Accessories and adaptations

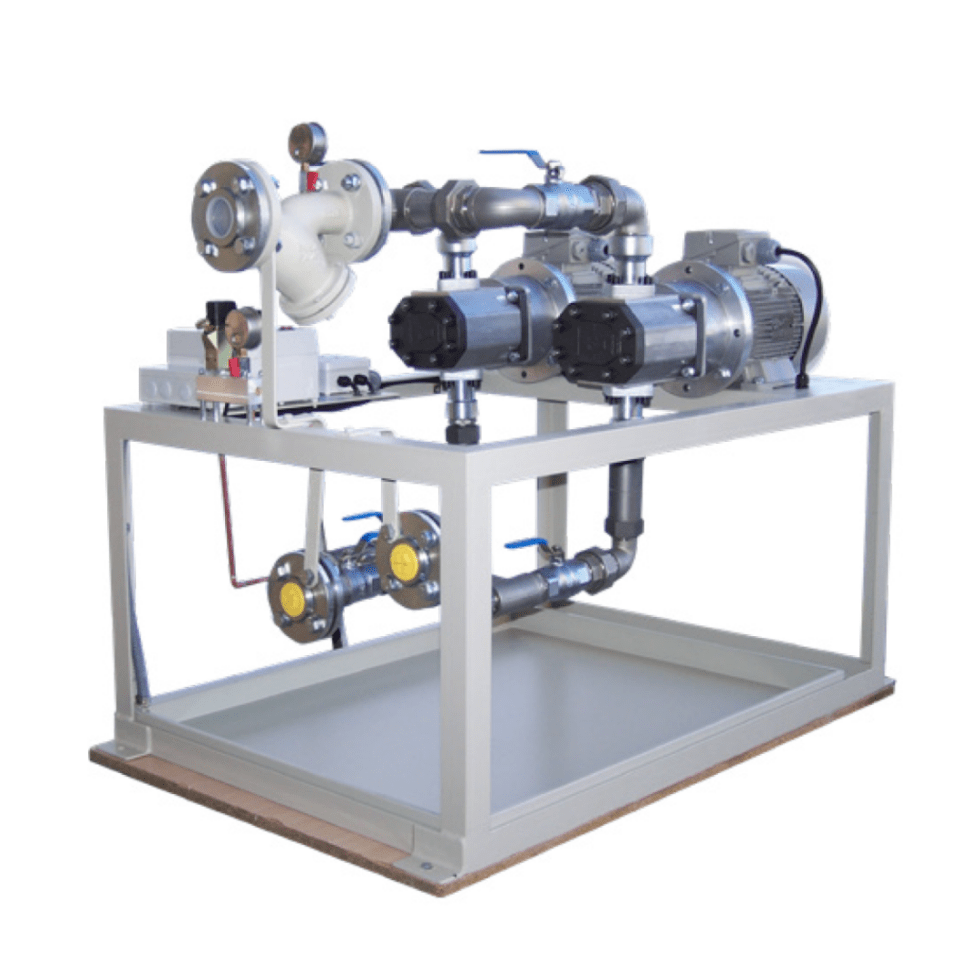

-Special non –ferrous metal free versions upon request.

-Standard motor power ready for viscosities till 38mm2/s (40ºC). For others, please consult.

-Oil failure control system, to protect gears running with an empty -tank.

-Free voltage relay output to control from centralized Building Management System, in kit 3, 4 or 6 signals (2-thermal, motors 1 or 2 ON, low pressure and Leak safety ON).

-GSM alarm system by SMS messages, or connection to modem.

-Adaptation of Pressure Group for high pressure, working conditions above 4,5 Kg/cm2.

-Leak collector trays with infrared detectors (standard in RL 4 and above).

-Modifications to adapt to specifically regulated environments (tropicalized equipment or ATEX).

-Solenoid valves with flow limiters, to automate fi

(*) Also available in 230 single phase versions (W/WD= 230 V. single phase version; D= 400 V. triphase versions). – For other capacity and mediums, please consult. – ZW: Two pumps versions 1) For viscosities till 38 mm2/s (40ºC)