Silane Gas Detectors from International Gas Detectors – We can provide a range of fixed sensors and portable gas monitors for the detection of SiH4.

It is important for many industries to have accurate and fast detection of silane to avoid the gas reaching dangerous toxic levels.

Discover our range of carbon silane detector and associated instruments. Designed specifically for the detection of SiH4. Our silane gas detector range includes:

TOC-750 Addressable Safe Area Gas Detector

TOCSIN 903 Standalone Explosion Proof Gas Detector

TOC-750X Explosion Proof Addressable Gas Detector

TOC-30 Analogue (4-20mA) Gas Detector

TOc-750S Aspirated (Sampling) Addressable Gas Detector

(Short Term exposure Limit – 15mins)

(Time Weighted Average – 8hrs)

0.5ppm

1ppm

Optional

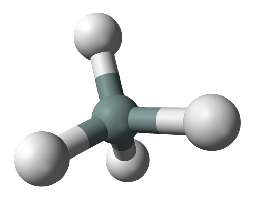

Silane (SiH4) is a colourless, flammable gas with a sharp, repulsive smell similar to that of acetic acid. It is pyrophoric gas meaning it can spontaneously combust and has a a wide flammable range 1.37 to 96% in air.

The greatest hazard of SiH4 is its unpredictable behaviour when released to the air with either delayed ignition, immediate ignition or no ignition. Most accidents occur due to ignitions/explosions caused by poor process handling and the pyrophoric nature of Silane. Changes in cylinder pressure, flow rate, confinement area, humidity, impingement on objects, etc. can cause ignition.

Taiwan, SiH4 Explosion, Nov. 23, 2005: During a cylinder change SiH4 was released from a full cylinder un-ignited. The metastable mixture ignited, fatally injuring the operator and rupturing the cabinet. Other silane and Ammonia cylinders in the gas room also started to release their contents causing a major incident. In some processes Nitrous Oxide is reacted with Silane to form a Silicon Nitride layer.

In two cases, Nitrous Oxide accidentally back-flowed into a Silane cylinder forming a metastable mixture. They reacted when the cylinder valve was opened causing adiabatic compression heat. In the Gollub incident 3 people were killed and 1 severely injured. At Osaka University 2 were killed and 6 injured.

It is of practical interest as a precursor to elemental silicon. Several industrial and medical applications exist for silane and functionalised silanes. For instance, its used as coupling agents to adhere fibres such as glass fibres and carbon fibres to certain polymer matrices, stabilising the composite material. In other words, SiH4 coats the glass fibres to create better adhesion to the polymer matrix.

Silanes applications include:

The semiconductor industry used about 300 metric tons per year of Silane in the late 1990s. More recently, a growth in low-cost solar photovoltaic module manufacturing has led to substantial consumption of Silane as part of the production process.

Our 750 Addressable safe area silane gas detector is the perfect solution for silane detection. With 7 I/O points per detector you can control a wide range of devices from the nearest ozone gas detector. Including, solenoid valves, audible visual alarms and other sensors. This drastically reduces cabling costs. Our 750 silane gas detector also features replaceable sensor fronts. This means you can easily replace the sensors rather than requiring an engineer to attend sites for calibration.

Couple this with our new 635 Gas Detection Control Panel (Pictured below) and you can have a small format silane gas detection system within minutes. The 635 features our industry first, One Click automatic system setup. Check out the webpage here for more details.

If you require an explosion proof detector we can provide this as our 750X addressable series zone 1 and 2 explosion proof silane gas detector. Or as our TOCSIN 903 standalone ATEX/IECEx transmitter which features 4-20mA output and relay outputs.

Finally we can also provide a range of portable silane gas detector devices, both ATEX and safe area, for personnel protection and alarm verification with fixed systems.

Enter your Email to get newsletter

SALALAH OIL AND GAS INTERNATIONAL

SOGI is a top oil and gas trading company, delivering high-quality products, customized solutions, and expert support, all committed to industry standards and environmental responsibility.

Copyright © 2024 – Salalah Oil and Gas Company